The modern scientific research market has become extremely competitive providing viable alternatives to laboratory furniture. Recognizing the unwavering competition, and changing demands there is a wide range of flexible laboratory furniture. One such important laboratory furniture is the Fume Hood system that controls the release of toxic and hazardous substances into your working laboratory station/ workplace. Therefore, in this comprehensive content, we will encompass a substantial understanding of the Fume Hood Working Principle and draw your attention to India’s leading turn-on ISO-certified fume hood solutions manufacturers.

Let us start with the important points on what is a Fume Hood and what is it used for.

Fume Hood– As the word refers, fume means vapors, gases, and smoke that can result in reactions like heating, explosion, and detonation. On the other hand, hood alludes to the idea of coverings. Fume hoods are enclosed-ventilated safety laboratory furniture that ventilates dangerous fumes and gases and oxygenates the fresh air. The chemical laboratory exhaust system has an advanced filtration technology that safeguards the integrity of the experimental results and protects the workers from inhaling toxic substances and gases.

What is a Fume Hood Used For?- These are the most reliable constructions that allow users and scientists to deal with highly potent and hazardous chemical gasses, vapors, and synthetic substances. The ventilated fume hood plays a vital role in ensuring a protected working environment for researchers and workers and preventing them from various potential health diseases and risks. They are easy-to-maintain modular exhaust- furniture specially designed to enhance the overall efficacy of the working environment and streamline operations.

How Does a Fume Hood Work?

Long-term exposure to poisonous gases and hazardous substances in chemical workrooms can lead to serious health concerns and problems. This is where the sophisticated indispensable laboratory fume hood tool is used for filtration and exhaust mechanism against hazardous substances surrounding the work environment( lab space). Looking back, the fume hoods are an essential piece of equipment tool, recognized in 1923, and during 1990, it started to become widely accepted.

Fume hoods can emit dangerous vapors and harmful fumes quickly and people can stay safe without any accidental exposure. Now, let us delve deeper to explore the inner workings of the fume hood and uncover the major facts and secrets behind the intricated working in simple English language.

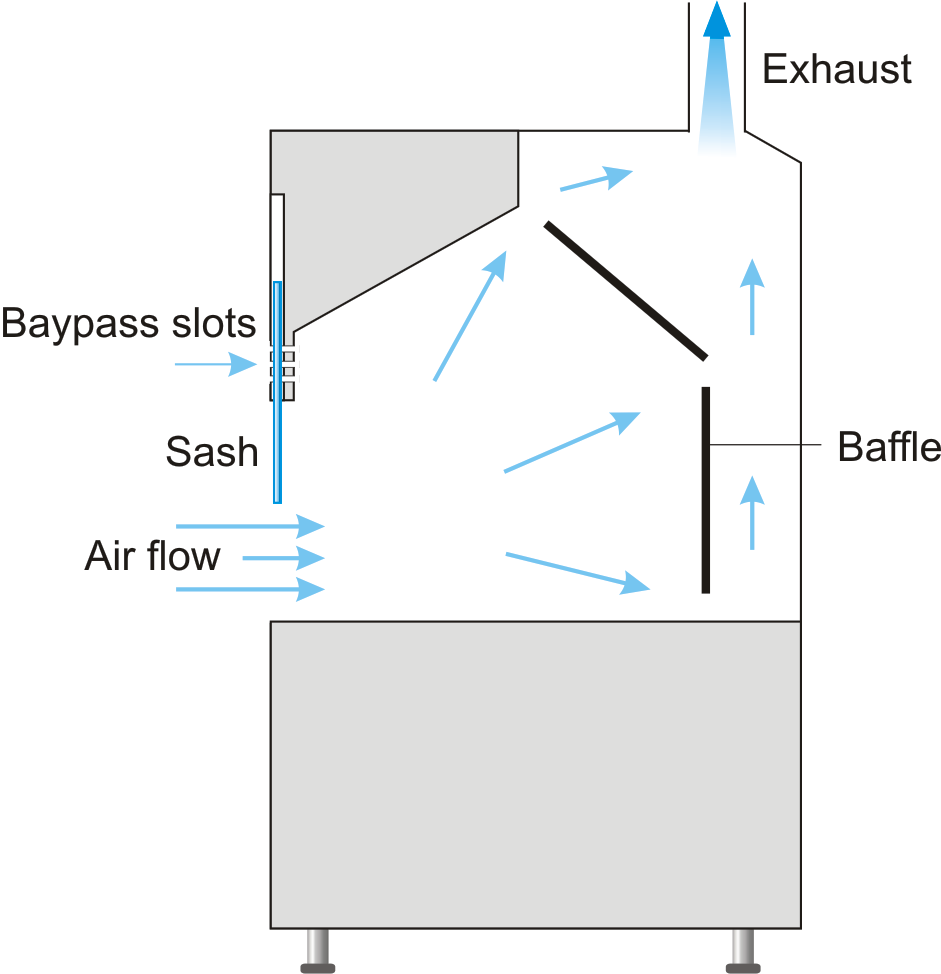

Demystifying Fume Hood Working Principle- Fume Hood is recommended when working in any kind of laboratory and is regarded as the most widely used approach for exhaust/ventilation mechanisms. Here, let us understand the Fume Hood’s inside parts and their process.

- Sash Control and Mechanism- At its core, laboratory hoods are constructed to control and capture hazardous substances and toxic gases. The enclosed workspace consists of a movable vertical or horizontal panel on the front portion of the fume hood. This is a protective barrier that can slide up and down or horizontally across the hood opening/ face. In simple terms, it is an open door or window that prevents leakage.

- Lighting Equipment– Quality and bright lightening like LED and bulbs are the critical aspects of the Fume hood device that provide clear and safe working visibility and enhance the productivity of the task/ experiments and testing.

- Sink- Fume hood sinks are similar to our kitchen sink that help in cleaning and rinsing laboratory equipment and glassware. They are essential engineering equipment that provides a water source in case of health emergencies like eye-washing, hand-washing, face-washing, etc. This workstation plays an important role in maintaining a controlled work environment during experimental research and testing.

- Button Operating Switch- This is a user-friendly interface that provides an excellent mechanism to control various applications like sash operation, lightning and fan control switches, and alarm activation, along with some safety features like emergency buttons, shut-down or interlock buttons, etc. During the experiments, these buttons- operating switches also help in adjusting the positioning of the sash while working. They help in optimizing the proper airflow and ensure the safety of the working professionals.

- Sidewall- The side wall sensor is resistant to steam, corrosion, and chemical pills. These sidewalls include service fixtures, and electrical outlets, and are configured to measure the airflow. Unlike fume hood sash, side walls are constructed to create a containment barrier, minimizing the risk of leaks and facilitating optimal airflow.

- Air Flow Velocity/Principle– This determines the fume hood performance, adequate face velocity between 0.3ms/ to 0.5ms that passes across the plane or face of the fume, airflow velocity, measures the standardized routine experimental task, etc. This is the most substantial tool in the chemical fume hood laboratory that controls and monitors the airflow in real time. Air face value depends on the area of the opening of the fume hood. It is important to reach the standardized face velocity during an experimental setup.

- Baffles- These are adjusting- movable partitions that regulate the flow of the air and ensure an appropriate ventilated workspace for working professionals and users. They play an important role in air-flow dynamics and patterns without compromising safety in different chemical laboratory workstations. Baffles, which are located below the exhaust duct direct the flow of liquid, gas, fluid, and other airborne particles.

- Exhaust System/ Blower- In laboratories, the contaminated air collected in the workspace, known as Baffles, is directed to the ductwork exhaust system or the filtration system outside the laboratory. Therefore, we can say that the mechanics of a fume hood is to remove contaminated air effectively and safely.

While choosing a fume hood divide for your laboratory and making any final decision, I recommend you underline the purpose of the hood and select the most promising fume hood supplier or manufacturers who can guarantee to protect you from harmful gases and fatal accidents.

What Types of Hazards Can a Fume Hood Protect The User Against?

Fume hood exhaust systems in the laboratory are essential engineering control types of equipment that adhere to effectiveness and safety protocols. Moreover, we have properly discussed the Fume Hood Working Principle in detail. Consequently, the paragraph below will assist you with what you need to know further on the hazards a fume hood protects the user from.

- These are not storage types of equipment; however, the fume hood is a special type of large box laboratory furniture mounted on the top of Lab tables to protect the users from inhaling chemical exposure to poisonous substances.

- These are the most prominent biosafety cabinets that control volatile organic compounds like ethanol and isopropanol alcohol to a comprehensive range of chemical acid and base fumes.

- Using a fume hood ventilation system is always advisable to minimize the risk of biological agents and hazardous chemical substances to skin absorption.

- They are appropriate filtration equipment/devices that can capture atmospheric particulate dust particles like chlorine, sulfur, etc, hazardous powders like bromide, sodium azide, etc, and aerosol suspensions.

- A chemical fume hood are specialized safety cabinet that comes with HEPA filters (High-efficiency particulate Air) that remove 99. 97% of biological particles such as bacteria, viruses, and porous particles.

- They play a crucial role in handling the dispersion of radioactive materials like uranium compounds, thorium chemical elements, etc by creating a barrier between skin contact or inhalation exposure.

- Fume hood electrical equipment makes an effective odor-free working environment for researchers and working personnel.

Hence, laboratory fume hood equipment is an important asset used in the laboratory that contributes to plenty of applications across diverse scientific disciplines from quality control to safety and efficiency of scientific research and experiments.

Start your Project with India’s Best Fume Hood Manufacturing Expert

As we have excavated the basics of the Fume Hood Working Principle above, now is the time to embark on your project journey with the Fume Hood specialist safeguarding your meticulous laboratory experiments. Certain stringent salient factors set the leading manufacturers apart and turn your attention to embodying the best fume hood solutions.

Shapers Lab in Vadodara, Gujarat stands as a beacon for a diverse range of fume hood solution systems since 2008. The renowned manufacturers have become the brand name among the global players by offering the latest and most sophisticated fume hood systems to clients. Above all these, the engineers and technical staff at Shapers Lab have unparalleled expertise for leveraging advanced fume closet cupboard designs and engineering techniques through their extensive research and development.

As we continue to grow, let us work together to foster and enhance your productivity.

Contact us soon for the extensive fume hood product portfolio at a competitive cost-edge pricing.